As a result of deficiency of deviations in precision machining, there are actually much less defective productions. So the procedure contributes to a lower rejection fee of parts. Thus, the price of materials is decrease.

As we transfer into your 2030s, mass production will ever more count on advanced CNC machines equipped with AI and machine Finding out.

Precision machining is usually used on various metals, polymers, and composite materials. Below are a few typical CNC machining materials for precise machining:

Inside the 2030s, job retailers will probable keep on to evolve with developments in CNC technology, like automation and intelligent manufacturing. These improvements will permit work retailers to offer even more quickly and a lot more efficient expert services, keeping their aggressive edge out there.

CNC automation enables electrical discharge machining (EDM) in two ways. It allows vertical EDM requiring electrodes with a similar form and size given that the cavity to generally be carved out.

Among the finest approaches to attenuate the price when retaining the highest high-quality precision machining will be to outsource the procedure to 3ERP.

He reported he wasn't aware about I Machine Technology’s ties on the Russian military services. “Distributors mainly have quite a few consumers,” he stated.

For example, wooden legs for any eating table may be made with a straightforward CNC lathe, and metal cutting can be done with electrical discharge machining. Here are a few in the household furniture applications of a CNC machine:

The recently produced missile, effective at carrying multiple nuclear warheads, was demonstrated during an October military services exercising that simulated a retaliatory nuclear strike.

It operates in an arranged fashion, turning structure requirements into Actual physical components with extreme accuracy. Here’s a stage-by-action overview of its processes:

CNC machining during the healthcare and healthcare industry is used for manufacturing healthcare supplies and swift tooling to develop dies for injection molding. Then, the injection molding here approach provides equipment like confront masks.

CNC milling is really a subtractive manufacturing method that uses rotary cutters to eliminate materials from an item. Distinct cutting outcomes is usually achieved by various the angle, course, stress, and cutting tool speed.

If the set up is finished, the machine system is able to operate. Most CNC machines include a Show for monitoring This system and altering numerous options. When This system is operate, the CNC machine will start precision CNC machining.

As we strategy the 2030s, the die and mold industry will take pleasure in even further improvements in multi-axis machining and significant-pace CNC technology.

Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Mara Wilson Then & Now!

Mara Wilson Then & Now! Dylan and Cole Sprouse Then & Now!

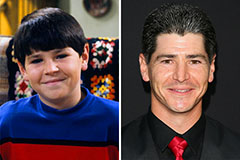

Dylan and Cole Sprouse Then & Now! Michael Fishman Then & Now!

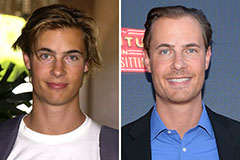

Michael Fishman Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now!